The incineration process is the longest known method of thermal waste management. The term incinertaion refers to the oxidation of fuel in a boiler or furnace to obtain heat. Incineration occurs in the presence of oxygen, which is extremely important due to the formation of dioxins and furans harmful to health. The dioxins and furans formed with the participation of oxygen very strongly disturb the hormonal balance of the body, leading to the occurrence of many dangerous diseases. The heat produced can be used to produce hot air, hot water, steam and electricity. Incineration requires very high ignition temperatures, sufficient turbulence to mix all components with the oxidant and the appropriate end time of all oxidation reactions.

Pyrolysis, in contrast to combustion, does not require oxygen. The lack of oxidizer is beneficial, as dioxins and furans harmful to health are not produced, as well as nitrogen and sulfur oxides, which is why pyrolysis installations do not require expensive technologies to remove harmful compounds. Therefore, pyrolysis does not require the use of expensive purification and monitoring equipment that is required for incineration. In addition, it is also cost-effective to build smaller local installations.

The main difference between pyrolysis and incineration is the absence of oxygen in the process in the case of pyrolysis. In addition, it should be noted that in the direct oxidation process, the product is heat and waste – dust and slag, large amounts of waste generated in incineration plants are far from the idea of “zero waste”. The pyrolysis process results in a significant reduction of mass, and products are produced in the form of fractions that can be used for energy purposes as alternative fuels.

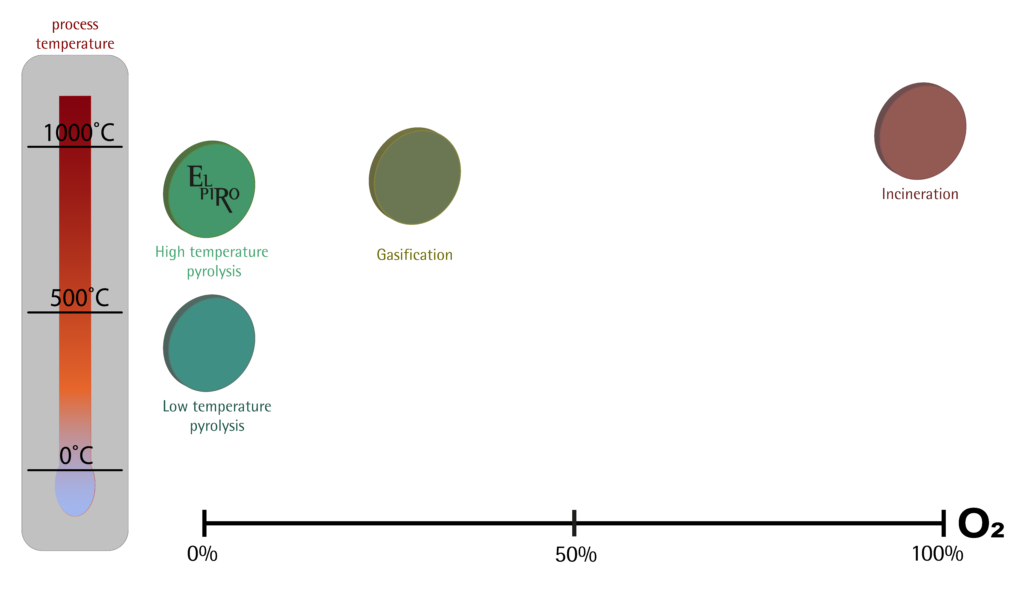

Fig. Comparison of pyrolysis and incineration processes

The resulting pyrolysis and incineration processes:

- High temperature pyrolysis (for example EL PIRO):

In this process, the main products are gas and biochar, heat is also generated

- Low temperature pyrolysis

In this process, the main products are oil, gas and biochar, heat is also generated

- Incineration

In this process, the main product is heat and in the form of waste – dust and slag. Due to the access of oxygen in the process, harmful dioxins and furans are formed.

Sources:

Introcuction to biorafineries and biofuels Assignment 8: comparison of gasification, pyrolysis and combustion, Aalto University School of Chemical Technology 2013

Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge to energy management in Greece, M.C. Samolada, A.A. Zabaniotou, Waste Management, 2014

Life cycle assessment of pyrolysis, gasification and inceneration waste-to-energy technologies: Theoretical analysis and case study of commercial plants, J. Dong, Y. Tang, A. Nzihou, Y. Chi, E. Weiss-Hortala, M. Ni, Science of the Total Environment, 2018