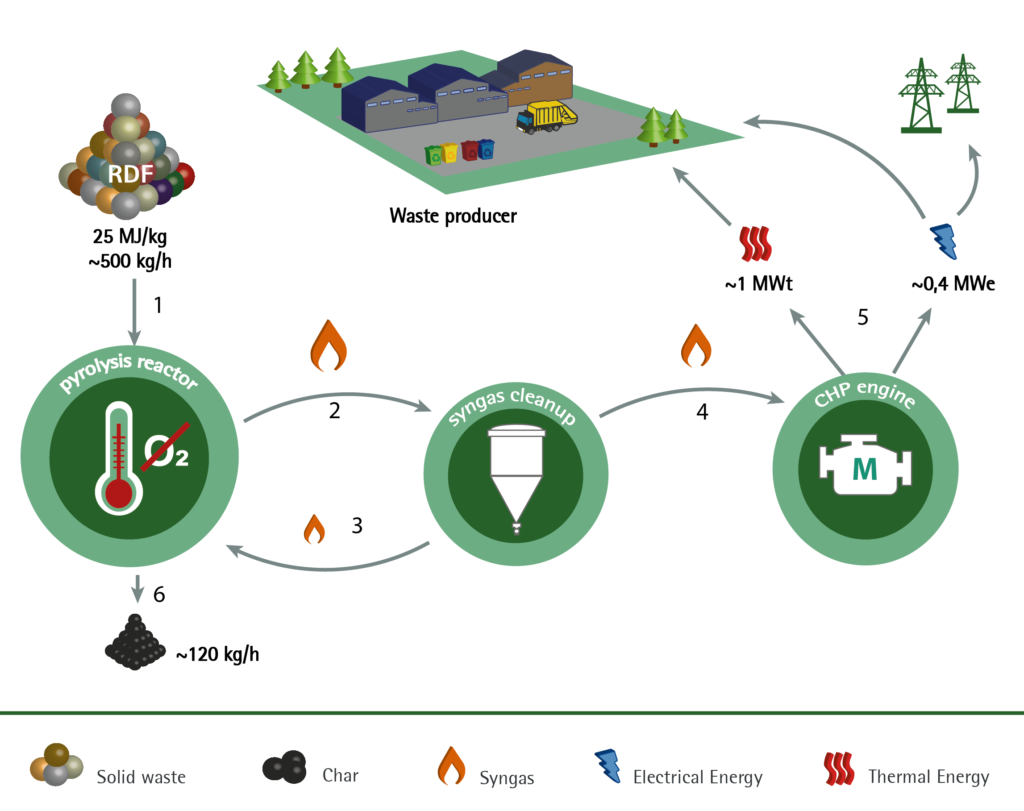

Non-recyclable waste, due to its high calorific value (over 6 MJ / kg), is a problem for most waste treatment plants, because according to the law from 1 January 2016, it cannot be stored. RDF as a product created from non-recyclable waste occurring in the form of, for example, a flake, can be used in energy recovery processes, such as pyrolysis. This method is environmentally friendly because, unlike combustion, the process takes place in a limited amount of oxygen.

Description of the technology:

- Specially prepared waste is subjected to a pyrolysis process inside an airtight reactor. Pyrolysis temperature range reaches from 800°C to 1000°C.

- High-calorific syngas produced in the process is dedusted and cleaned up from aggressive chemicals (Cl, S, F).

- Part of the produced syngas is used to power the pyrolysis burners making the process autothermal.

- Clean syngas is used as an alternative gas fuel to power an internal combustion engine.

- Silnik stanowi jednostkę kogeneracyjna do wytwarzania energii elektrycznej i energii cieplnej.Combined Heat and Power engine generates electricity and useful heat.

![]()

(download leaflet: CUTTING-EDGE METHOD OF SOLID WASTE PYROLYSIS Waste-to-energy ”EL PIRO” technology)

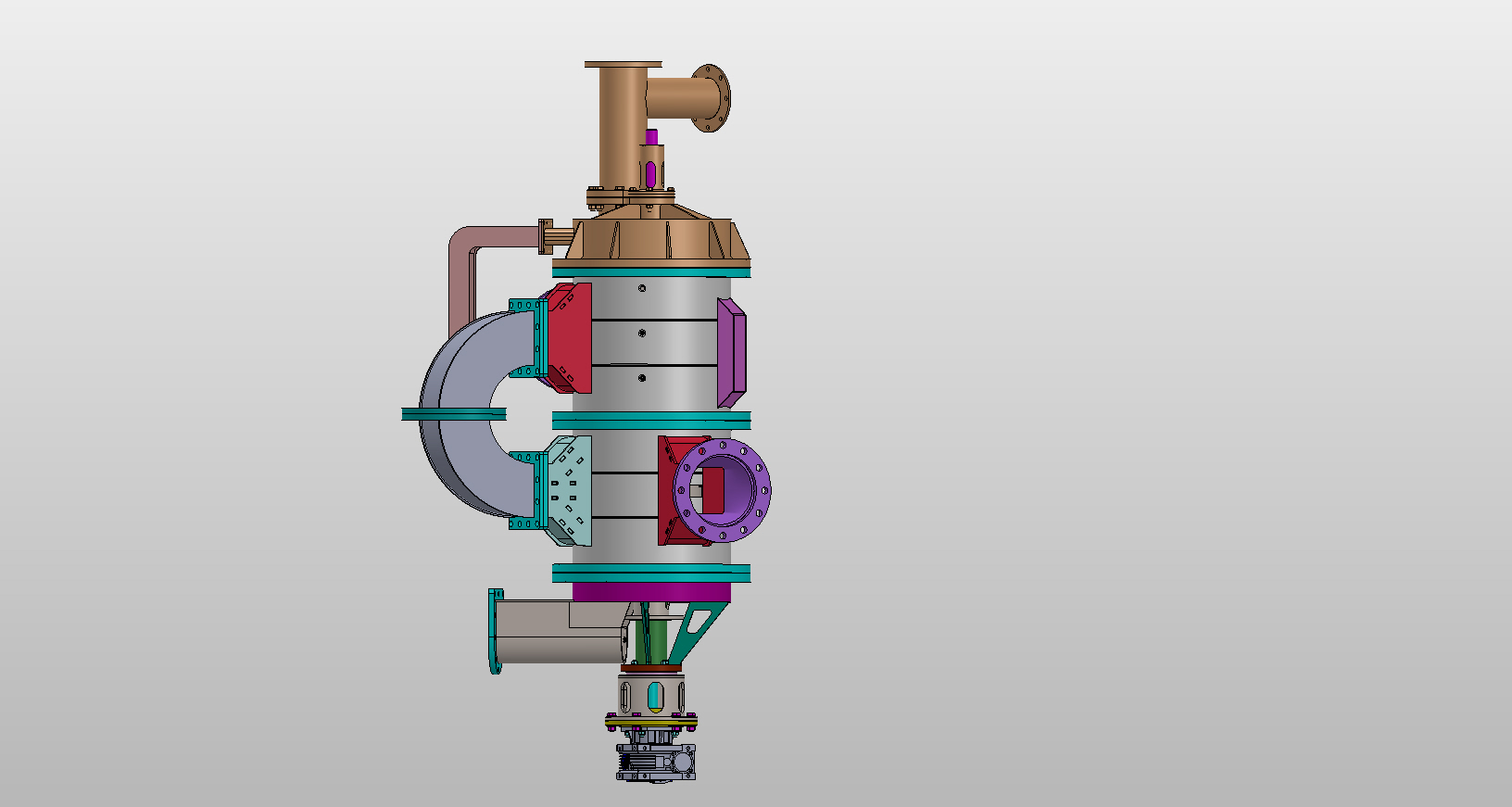

The currently designed and made reactor EL PIRO 2.0