Conducted selective waste collection allows to separate valuable raw materials such as glass, paper, metals and plastics from other waste. How to properly segregate waste you can read on the page Selective Collection and Waste Segregation. Therefore, only waste that is unsuitable for recycling like hygienic articles, ceramics, dirty bags and films, carbonless paper and copy papers, toys, unbreakable glass and glass, soiled or oily papers and foils, articles made of plastics with other materials, worn footwear, etc. should be thrown to black container – other (mixed) waste. Considering re-use or recycling, these wastes are unusable and should therefore be collected in a separate container.

At RIPOK (Regional Municipal Waste Treatment Plant), every part of the waste is weighed and then carefully sieved to select waste that can be segregated. Organic fraction (so-called biological) are processed on site, while glass, metal, plastic and paper are sorted for recycling. In the case of RIPOK having Refuse Derived Fuel (RDF) production lines, additionally after separating materials that are not recyclable, the appropriate high calorific fraction is transformed into fuel, only the remaining ballast is destined for landfill.

Recycling levels in the coming years

According to the National Waste Management Plan 2022 (referring to EU requirements) adopted by Poland for the coming years, it is assumed to achieve the level of recycling and preparation for re-use of fractions of paper, metals, plastics and glass from municipal waste at a minimum of 50% of their mass by 2020 The next stage is reaching by 2025 60% recycling of municipal waste. By 2030, 65% of municipal waste should be recycled. A very important provision is the obligation to reduce the municipal waste lanfilling to a maximum of 10% by 2030.

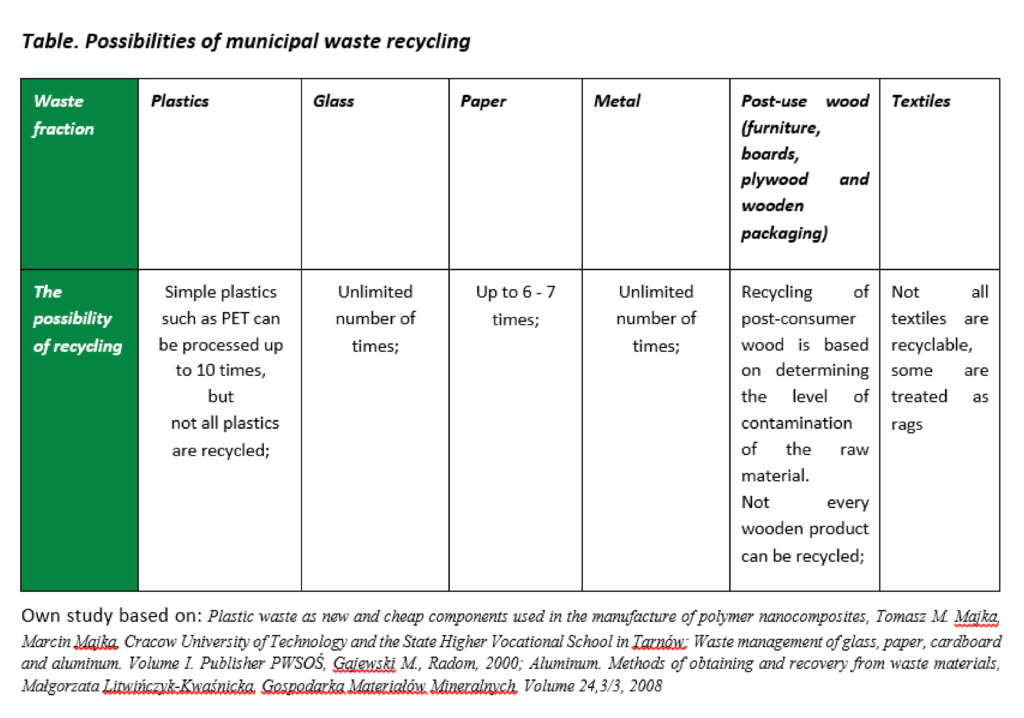

Increasing the levels of waste segregation at source will increase the level of recycling and will help to achieve the set goals. Recycling of different waste fractions can be carried out with varying results over a different period of time. The easiest process and used for many years is the recycling and re-use of metal and glass. Paper (only the one that does not have greasy dirt) is also an element used for the production of new paper materials.

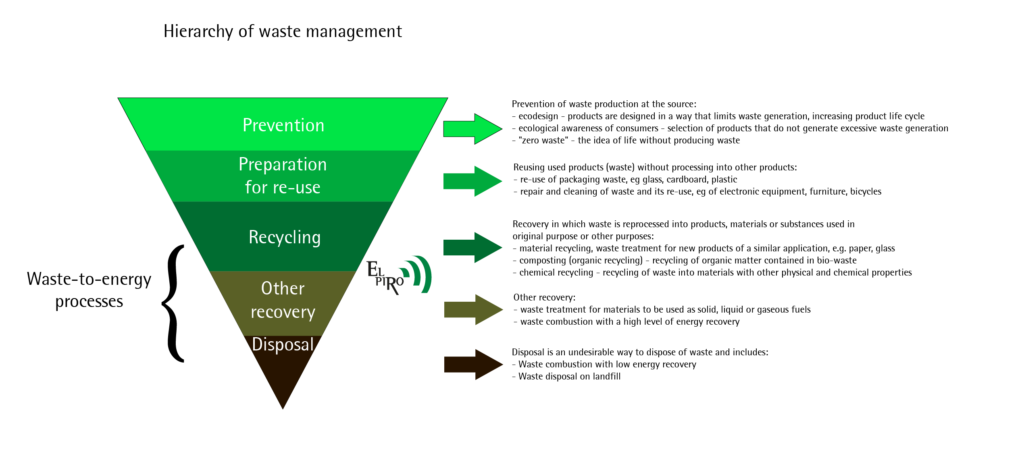

Fractions that cannot be subjected to processes preparing them for re-use should be managed in a different manner consistent with the hierarchy of waste management.

Fig. Examples of waste-to-energy processes in the hierarchy of waste management

Source: The role of waste – to – Energy in the circular economy, Communication From The Commission To The European Parliament, The Council, The European Economic And Social Committee And The Committee Of The Regions, Brussels, 26.1.2017

Waste Act of 14 December 2012

Ostatnim elementem w hierarchii jest składowanie odpadów. Aby ograniczyć ten rodzaj postępowania z odpadami wytwarza się tzw. paliwo alternatywne RDF, które ze względu na swoje właściwości (wysoką kaloryczność), może zostać poddane termicznemu przetwarzaniu z wysokim odzyskiem energii.

The last element in the hierarchy is landfillingo waste. To reduce this type of waste management, the high calorific refuse derived fuel (RDF, also called alternative fuel) is produced and then subjected to thermal processing with high energy recovery.

In Polish law, the term “alternative fuels” appears in the ordinance of the Minister of the Environment of 9 December 2014 on the waste catalog, under the code 19 12 10, where there are combustible waste (alternative fuel). These wastes are included in group 19 12 – waste from mechanical treatment of waste (i.e. manual processing, sorting, crushing, granulating) not included in other groups.

Non-recyclable waste – RDF fraction

Literature includes the definition of an alternative fuel RDF (Refuse Derived Fuel) as a material that increases recovery from municipal waste. RDF is a priority solution in industrialized countries. It is a material with high calorific value and homogeneous particle size. The physicochemical properties of alternative fuels depend on the type of waste from which they were produced. Alternative fuel (RDF) is currently produced in Poland from the over-sieve fraction of waste (80-100 mm), with a calorific value of 16-20 MJ / kg. The main components of these fuels are non-recyclable waste (the so-called residual fraction), such as:

• plastics,

• paper,

• textiles,

• composite waste

• wood.

Currently, RDF is mainly used in cement plants and partly in waste incineration plants (most of the incinerators use directly mixed waste). However, the processing capacity of these installations is insufficient to process the full amount of RDF.

Fot. RDF petal

Source: Own materials

RDF is a waste that is also well suited for other thermal processes such as gasification or pyrolysis. Complementary installations, such as pyrolysis installations, complement the waste life cycle. Pyrolysis due to its properties – the reaction takes place without oxygen, so it is an ecological way to develop RDF. The process produces new products that can be used in energy production and can also be classified as chemical waste recycling.

Źródła: Gasification of refuse derived fuel in a fixed bed reactor for syngas production, A. K. Dalai, N. Batta, I. Eswaramoorthi, G. J. Schoenau, Waste Management 29/2009, s. 252-258.

Possibilities for application of alternative fuels in Poland, Martyna Nowak, Mateusz Szul, Instytut Chemicznej Przeróbki Węgla, Zabrze, 2016