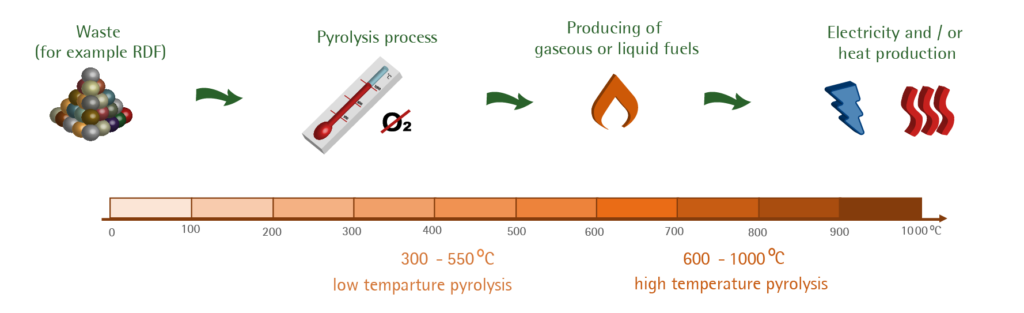

Pyrolysis enables recovery, often classified as chemical recycling of raw materials, calorific fraction of waste such as: RDF, plastics, sewage sludge, biomass or rubber (tires). During pyrolysis the decomposition of complex chemical compounds into compounds of lower molecular mass under the influence of temperature occurs. The effect of this process is to obtain high-calorific products such as gas, char, and oil. The characteristic feature of pyrolysis (which distinguishes it from combustion and gasification) is that the process is carried out without the use of oxygen, which eliminates the production of substances harmful to the environment and man.

The composition and quantity of pyrolysis products depends on the type of waste, its physicochemical properties and the process temperature.

Pyrolysis types

- Low temperature pyrolysis

Niższe temperatury procesu około 300 – 600˚C skutkują wytworzeniem oprócz gazu i karbonizatu również dużej ilości frakcji oleistej. Piroliza taka najczęściej stosowana jest do zagospodarowania odpadów ze zużytych opon, tworzyw sztucznych oraz biomasy.

- High temperature pyrolysis

High temperatures of the pyrolysis process (600 – 1000˚C) ensure the production of a larger amount of alternative fuel in the form of gas, desired for generating electricity and heat in a cogeneration system. High-temperature pyrolysis allows thermal treatment of waste to gas with a high content of hydrocarbons (methane and carbon monoxide and hydrogen), which can be a fuel for use in a CHP unit or a steam boiler. The amount of gas obtained from RDF is about 60 to 80% by weight.

Fig. Pyrolysis process – producing fuels

Source: Own study

Sources:

Introcuction to biorafineries and biofuels Assignment 8: comparison of gasification, pyrolysis and combustion, Aalto University School of Chemical Technology 2013

Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge to energy management in Greece, M.C. Samolada, A.A. Zabaniotou, Waste Management, 2014

Life cycle assessment of pyrolysis, gasification and inceneration waste-to-energy technologies: Theoretical analysis and case study of commercial plants, J. Dong, Y. Tang, A. Nzihou, Y. Chi, E. Weiss-Hortala, M. Ni, Science of the Total Environment, 2018